Aquatic

Testing

Our Testing Standards

Accelerated QUV Testing

QUV accelerated weather testing reproduces the damaging effects of UV sunlight and moisture on polymer coatings in a laboratory environment. The test accelerates the damage that would normally occur over the span of years to that of only days or weeks in the high-intensity chamber. Using standard ASTM testing methods, samples placed in the QUV testing chamber are bombarded with sunlight spectrum UV light, in alternating dry and wet cycles, and elevated temperatures. Although there is no established direct correlation between hours exposure in a QUV tester and years of actual exterior sunlight exposure, QUV is an industry accepted method of predicting polymer performance throughout years of exterior exposure service.

The photo shows two samples of EcoFinish™ aquaBRIGHT™ Pool Finish. The sample on the left was exposed to 3000 hours of QUV testing while the other sample was literally kept in the dark as a comparative standard.

The result of the 3000 hour test revealed no visual indication of color change or gloss loss from the damaging effects of UV exposure. We can’t see any change, and neither will your customers while they enjoy this worry free swimming pool finish for may years to come. Just one more reason why we have the confidence to warranty aquaBRIGHT™ for 10 years.

Non Slip Textured Application

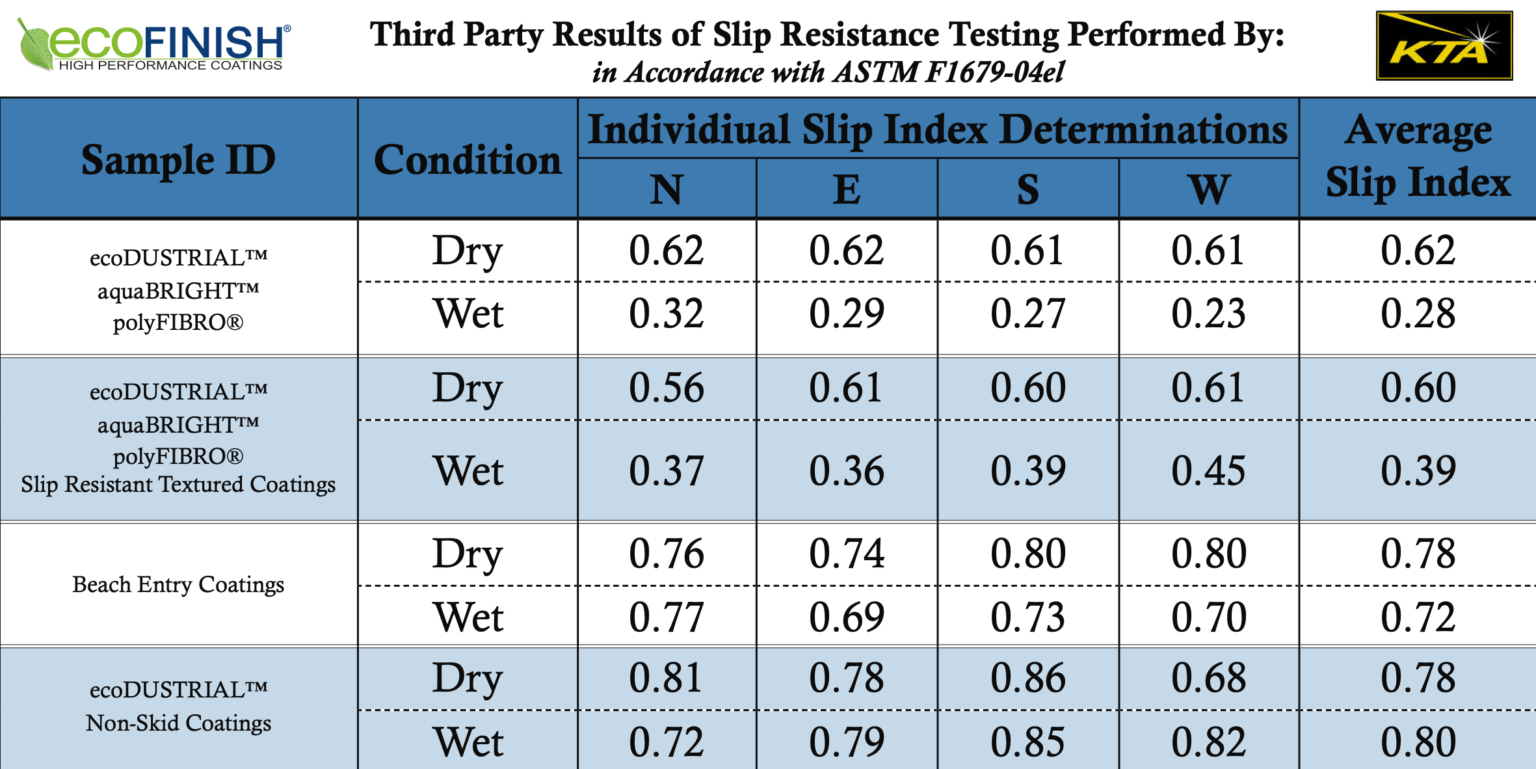

Slip Resistant Application for aquaBRIGHT™ and polyFIBRO®

Any aquatic area with high traffic, such as slide entrances, zero-entry, and wading pools, can safely have aquaBRIGHT™ and polyFIBRO® applied to them. Our slip resistant application process for aquaBRIGHT™ and polyFIBRO® is ideal for surfaces such as steps, benches, and beach entries to assist in the prevention of accidents at ingress or egress points in a pool. This is a special application process using same high quality tested materials. Be sure to contact your representative for more details. *

*If you are looking for the non skid abrasive coating visit our ecoDUSTRIAL line. The abrasive coatings are not recommended for aquatic entryways or features.