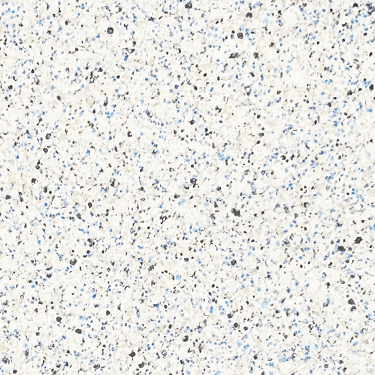

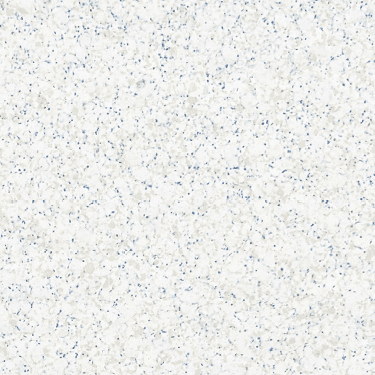

aquaBRIGHT™

For decades swimming pools were coated in a silky white rubber-based paint finish. In addition to the smooth texture and bright white look, this type of paint was known for its durability against stains and imperfections. During the late 1980’s, government regulations banned some of the most crucial ingredients that made this product maintenance free. New paints were no longer free of imperfections. Blistering, chipping, peeling, and fading began to appear in as little as six months.

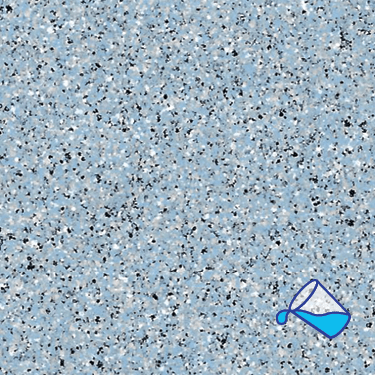

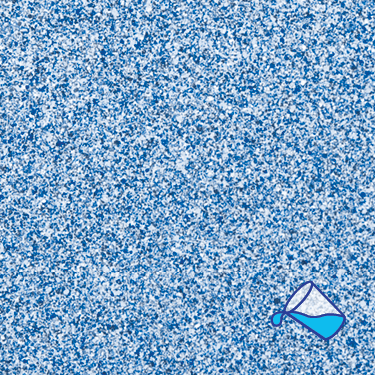

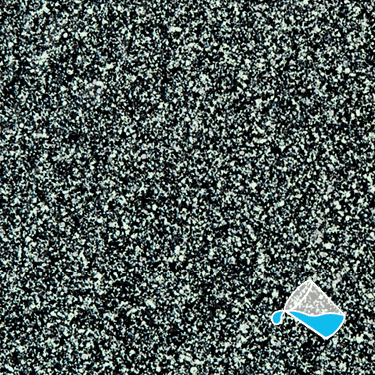

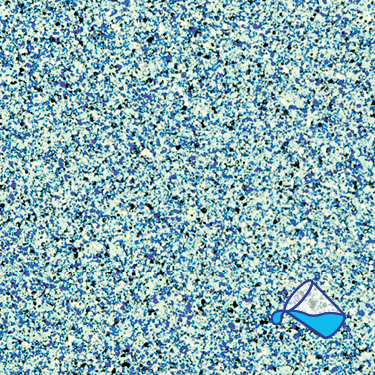

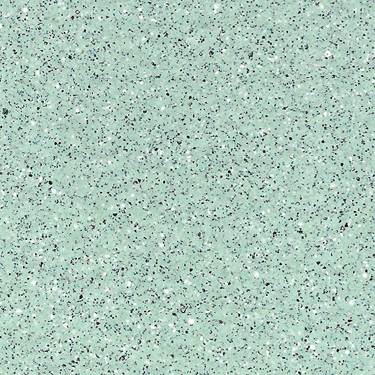

This forced swimming pool builders in many regions to switch to plaster finishes. Plaster has its own set of issues, in the form of a long and complicated start-up process (Hot-Start), as well as staining, shrinking, and cracking problems. aquaBRIGHT™ was scientifically developed to present a solution to these pool finish problems. The long-lasting thermo-polymer finish, aquaBRIGHT™ is the wave of the future. For fiberglass coatings, inquire about our polyFIBRO swimming pool finishes.

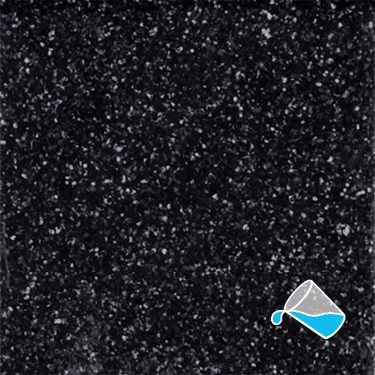

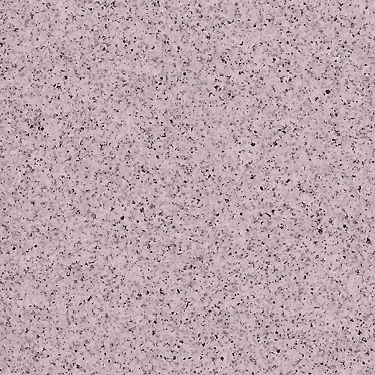

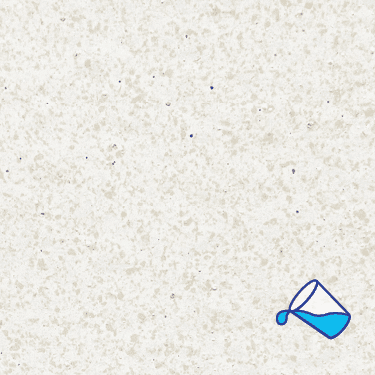

* The full range of ecoFINISH® colors is available for all ecoFINISH-suitable surfaces, However, approved surfaces require different preparation methods.

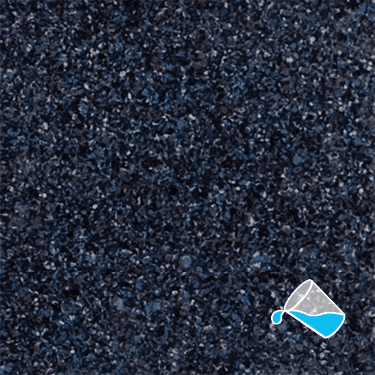

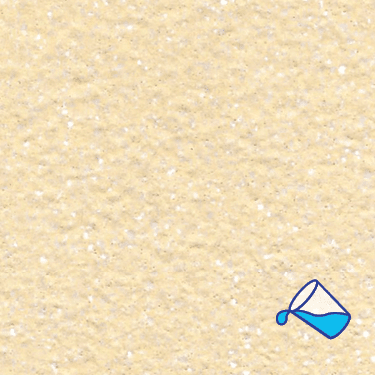

Limitless Possibilities

Choose any color for any ecoFINISH processAdditional aquaBRIGHT™ Facts

and Information

Our aquaBRIGHT™ Warranty

Discover our warranty options, providing confidence and peace of mind for both residential and commercial pool projects. Your satisfaction is our priority.