Pool Magazine Podcast – Learn More About ecoFINISH

Introduction:

In a recent two-part podcast series on Pool Magazine – Podcasts for the Pool Industry, the spotlight shone on ecoFINISH. Part one features Jacob Tetrick of Quality USA Pools, who shares his hands-on experience with ecoFINISH products. In part two, the discussion continues with ecoFINISH’s President, Joe Solana, delving into the company’s history and their innovative pool coating products.

We’ve provided a full transcript for both episodes, so get ready for a deep dive into ecoFINISH with this engaging podcast series.

Part 1 – Jacob Tetrick

Pool Magazine: Thanks for joining us on another episode of Pool Magazine Podcast. You know, frequently we spend a lot of time in a lot of the pool industry Facebook groups, and a really interesting post about ecoFINISH recently popped up on Ask The Masters, a group where a lot of the top designers and pool builders hang out. Now folks are interested in the product and have been asking around trying to find some more information about whether it’s a good solution, who’s used it, and what the results were like.

Now personally, I know a lot of people in the pool industry, so I decided to reach out to my friend Jacob Tetrick, owner of QualityUSA Pools.

I know his firm specializes in ecoFINISH installations, and I couldn’t think of a better pool pro to ask about his first hand experience using the product. It’s a pleasure to have you with us today on the show.

Jacob Tetrick: Thanks for having me.

Pool Magazine: So listen, before we get started, I mean, I was hoping that you can give our audience a little bit of a backstory about QualityUSA, what it is you guys specialize in, and what your firm is all about.

Jacob Tetrick: So I started QualityUSA Pools about four years ago now, because I had a bad experience at a pool store, and wanted to provide better customer service. And along with that, comes providing superior products. We specialize in new pool builds and remodels. So we build vinyl liner pools, we only use alpha pool products for all of our panel systems. So we use their evolution panels for our higher end pools. And then we use their Titan panels for the steel panel vinyl liner pools.

The Need for ecoFINISH

Pool Magazine: When did you first start looking at ecoFINISH as a solution for your pool finish applications?

Jacob Tetrick: So I first started looking at it as I got more inquiries about if we do renovations or not. With the growing demand for people looking for resurfacing, there was also a need for a higher end pool that was done in a faster time frame, and not as invasive in their yard, so to speak. And some people where I live in South Dakota, they do not like the idea of a full concrete pool. They don’t like the price, there’s big price differences. And a lot of times it’s not always about the cheapest, it’s they want to spend more money on a superior product. And so that’s what really got me to look at the different options.

And I found ecoFINISH by looking for ways that were the latest and greatest, so to speak, looking for superior products that I could put in with a minimal amount of employees. I know I’m not alone, not even just in the pool industry, we’re not alone. Every industry in the country for whatever reason has a really, really hard time finding people to actually help do the work.

Pool Magazine: Yeah, staffing’s a big issue right now. So this solution allows you to cut down on the employees that you have out on a job site?

Jacob Tetrick: Yeah, so even on a complicated resurfacing project where we have to chip out plaster and put a skim code on a concrete pool that we’re going to resurface, we can do it with three guys. It’s a lot of work, but that’s all we really need. More than that, and it just ends up kind of being a nightmare.

Benefits of ecoFINISH

Pool Magazine: Well, what were some of the main features and benefits about this product that kind of drew you to it?

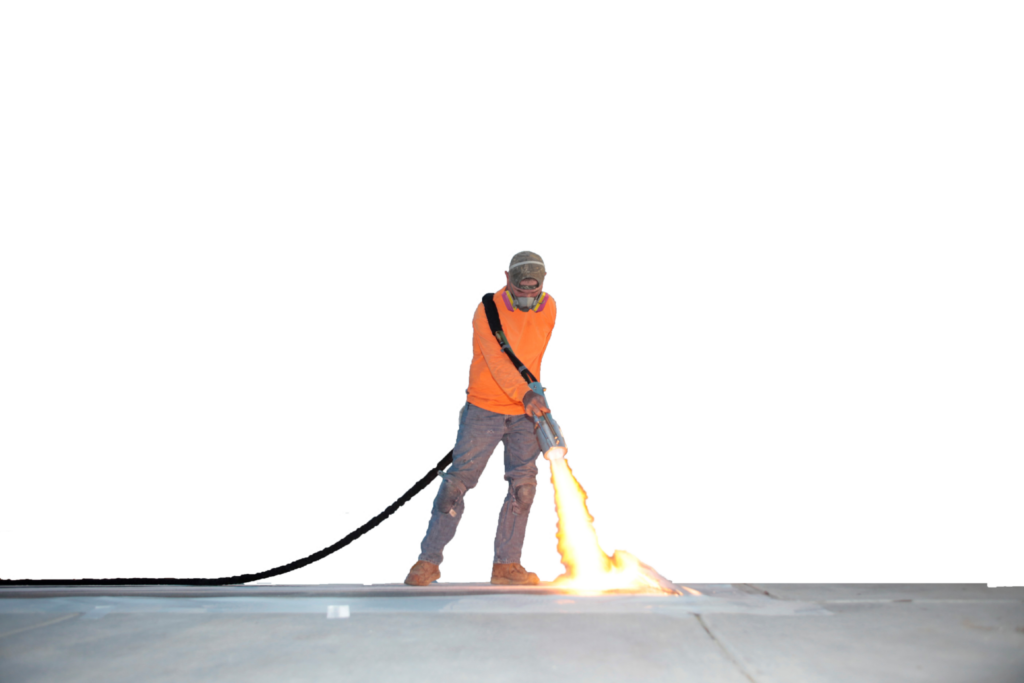

Jacob Tetrick: Well, I mean, who doesn’t think playing with a flamethrower is cool? That was probably the thing that piqued my interest the most. And then aside from that, it’s the fact that it doesn’t fade in the sun, it’s got a 10 year warranty, it’s chemical resistant, all those things they speak for themselves. When it’s me looking at it going, okay, I want to provide the best possible products out there for the best possible price for me and for the customer. I mean, I want to make money and I want to provide the customer with a good long term solution so that I don’t have to have them call me every six months because there’s some sort of a problem.

Jacob’s Experience with ecoFINISH

Pool Magazine: Well, what has your experience been like using a product like this in comparison to some of the others you’ve tried out there?

Jacob Tetrick: My experience so far has been wonderful. I’m a fairly new installer. I got into being an ecoFINISH installer about a year and a half, almost two years ago now. And the best thing about it is how simple it is. As long as you follow their process and you do the prep right, you take your time and you apply the product properly, there’s no issues. I have it on residential pools, we’ve done concrete pools, we’ve redone fiberglass pools, fiberglass is a little bit more complicated just because of the fiberglass shell itself and the heat that the gun produces. But I’ve had no issues whatsoever. I’ve read the good and the bad about ecoFINISH that’s out there and I’ll tell you right now, it’s all in the installer. If you want it to be an awesome product that it really is, it can be. You just have to follow their process.

ecoFINISH Training and Support

Pool Magazine: Well, how did you learn the application process? Did you go on for any special training with the manufacturer or anything like that?

Jacob Tetrick: ecoFINISH actually has a very, very wonderful program. The guy that I’ve had come out, his name is Cory. He is wonderful. He over-explains, he gets right in and if you’re doing something wrong, he actually shows you how to do it differently. For me, I’m more of a learn as I do more than sit back and read a book. Probably a lot of people can relate to that.

That’s probably the thing that I like the most about ecoFINISH is it’s as hands-on as you want it to be. It’s no different than anything else. If you want it to work, you make it work. If you don’t want it to work and you just want to blame this, and blame that, and not take responsibility yourself for doing it right, or whatever, it’s not going to work. But this is by far the most superior product that I’ve run into the ease of installing. It’s wonderful.

Pool Magazine: I know a lot of guys learn best hands-on. It’s great that ecoFINISH has a rep that they sent out there to supervise your installation and kind of give you the whole of pro tips to get you inundated with the product.

Jacob Tetrick: Yeah, I couldn’t agree more. They send you all kinds of literature. They bombard you with all this stuff. They have some very wonderful things that they’ve put together that help you to sell the product. Even the national sales manager is great. Anytime I ever have any questions, I can always get somebody on the phone. I can FaceTime them. I can show them exactly what it is that I’m having trouble with.

Pool Magazine: That’s wonderful. I kind of support it. I mean, you’re in a small market kind of in South Dakota and that they still give you that kind of attention. It says a lot about your relationship with them.

Jacob Tetrick: Yeah, it’s like anything else that it costs money to get into. You got to buy the equipment and stuff and you pay for some of the training. And as a person going and buying the stuff and spending the kind of money that it takes to get into it, you always wonder. But like I say, I can’t say enough good things about them. They definitely, they definitely come through and then some, as far as support and training and even down to order in the products. If I need something last minute, it’s there always.

The Application Process

Pool Magazine: All right, well, talk to me a little bit about the installation process. I mean, I’ve seen your photos on social media. Yeah, there’s a flamethrower involved somehow. I mean, can you enlighten us a little bit about how the application process goes?

Jacob Tetrick: Yeah, so on a fiberglass shell, the first thing we’re going to do is we’re going to prep the shell. So we’re either going to dustless blast it or we’re going to sand it down. We’re going to fix any blisters or any cracks or anything like that. And then we’re going to come in and we’re going to put a layer of epoxy down. We’re going to let it tack up and then we put the product, which is like a dust is what it starts out as into the machine, hook our air and stuff up to it and our LP and start the flamethrower. And it’s kind of a slower process or whatever. Each coat on average probably takes about an hour, hour and a half. And it’s really quite an amazing process because you’re, you’re sitting there and you’re shooting out a four or five foot flame out of a gun that’s about eight, ten inches around. And it’s hotter than heck. And when you see how fast it changes the surface of the pool, you can see your instant results. It’s pretty amazing.

Pool Magazine: What’s the homeowner’s reaction like, Jake, when you show up in their backyard with a flamethrower?

Jacob Tetrick: The customers that have a pool in their backyard are a lot more easygoing on it than the ones where we come to an indoor one. Everybody is always in awe of it that you’re going to use a flamethrower. And then when they see it, they’re really in awe. And then when they see that they can touch it instantly, basically, it’s a secure product. I mean, within a few minutes, the whole shell of the pool has cooled back down and the product is hard already.

And I mean, it’s beyond words, the reactions that I get all the time from all of my customers, just because they can’t get over how much different it is right away. And then for the people that have a contrary pool or a shock reader, a gun, a pool, it’s even more amazing to them just because they don’t have to worry about replastering their pool right away. And it just changes the look of it so much. A lot of times, like a lot of the plaster pools that I see up here, at least are a lighter color. And so a lot of my customers are going with darker finishes and they’re just over the moon excited about how wonderful it is.

Longevity of ecoFINISH

Pool Magazine: Give us the elevator pitch, Jake. I mean, when you’re explaining why a homeowner should consider getting an ecoFINISH, what is it that you tell them? What does it do? And how does it work?

Jacob Tetrick: So if I’m going to a customer that’s getting a new pool, I simply explain the difference. Like I said, for me, it’s either a vinyl liner, or it’s a composite panel concrete bottom ecoFINISH pool. And so I explained the liners only last so long up here, we’re seeing three to seven years for liners, how long are they’re lasting? We get anywhere from $7,000 to $13,000 to replace a liner.

Well, you add that up over the course of just the warranty on the ecoFINISH, alone. The 10 year warranty on the ecoFINISH, compared to replacing a liner twice. The difference in the price of the pool basically pays for itself. I hit the warranty part real hard. I hit them with that it doesn’t fade in the song liners fade. It’s more of an eco-friendly coating. We’re not taking a bunch of vinyl, making a bunch of waste. And the biggest thing is that the evolution panels that I use from Only Alpha Pool Products, they have a lifetime warranty on them too. You throw all that warranty stuff together. And I’m noticing it sells itself and for peace of mind, right? Yeah.

Selling ecoFINISH to Homeowners

Jacob Tetrick: I have better luck selling the higher end pools than I do the lower end pools. And every day it amazes me. I sold a pool yesterday, been talking to the guy for probably two months about a vinyl liner pool. And he said, Hey, this pool that you’re building for my buddy, or whatever, what kind of pool is that? Is that one of your vinyl liner pools? And I said, No, that’s one of our composite panel pools that gets the ecoFINISH on it. And he goes, Well, I don’t even care how much more it is on price. That’s what I want. I don’t want a vinyl liner pool. That’s the only thing that’s been holding me back is I don’t want to replace the liner.

Application on Different Pool Types

Pool Magazine: Right. So I mean, you were talking for a second about how the process is a little different on concrete pools versus fiberglass pools. Can you elaborate a little bit about that?

Jacob Tetrick: Yeah So the fiberglass pools, the shell moves so much when it heats up. And so it almost pops and bangs at you. And it’s kind of scary when you’re doing it. You have to be really, really careful because you can actually wreck it. So we move around a lot. So we’ll do like a five by five section on one side of the pool, and then we’ll go to the other side. And we’ll do another small section. And we just keep moving around that way so that it gives that shell a chance to cool back down. Before we go and hit it again with more heat, the concrete pools, we don’t, we don’t notice that near as much because we don’t have the flimsiness, so to speak, of the fiberglass.

Pool Magazine: Yeah, it’s really malleable, that fiberglass material. Yeah.

Jacob Tetrick: And it’s, I mean, that flame is 780 degrees coming out of that cone. I mean, it’s, it’s hot. It’s interesting. That’s for sure.

Addressing Skepticism

Pool Magazine: Well, I mean, let me play devil’s advocate for a minute. How long does it last Jake?

Jacob Tetrick: It comes with a 10 year warranty. We’re seeing it well out last 15 years before it needs anything done to it. The coolest part about the product itself is, say, so we put it on a concrete pool. And we all know concrete moves, it cracks, all that kind of stuff. We can come back after the fact and we can, we can chase that crack. We can put staples in it. We can fill in the spot that we chased and, and then we can turn the flamethrower back on and we can coat right back over it. You don’t even know that we fixed it because it bonds to itself and it doesn’t fade. So it’s not like you have to go and completely redo the whole thing.

Thankfully, I haven’t run into any of that yet or whatever, but I’m sure I will at some point in time. There’s always problems with anything no matter what we do. I know I get a lot of questions while I read this about ecoFINISH, or I watched this video about ecoFINISH and my response is always there’s good and bad with everything, but it comes out to the installer.

One of the biggest things I use to my benefit is I only use superior products. I’m definitely not going to be the cheapest guy around. Hopefully I’m not the most expensive, but at the same time, hopefully I am. It’s okay to make money, and to sell a superior product. I always tell my clients that I can guarantee them two things: that I’m not going to be the cheapest guy, but I’m also going to use the best quality products that I can get my hands on. And not everybody can say that.

Conclusion

Pool Magazine: Well, I’m going to ask you this, Jake… The post on Ask the Masters was, “I have a sales person reaching out to me about the pros and cons of ecoFINISH. And I’m familiar with Marseille, Quartz, Pebble, etc. I saw all the downfall of rebound, but I’ve never heard of ecoFINISH, honestly. And the customer stuck on it as his previous pool had an ecoFINISH. Any experience? I’m curious just to further my knowledge base.” What would you say to this guy?

Jacob Tetrick: I would say that the ecoFINISH is probably comparable to a Pebble type finish, but the ease of application alone as a builder, I don’t understand why every single builder in the country wouldn’t say, I want to do that. And when you’ve got a customer that’s already had an experience with it and a wonderful experience to a certain extent, you’ve got to give the customer what they want. And if you go and you do your own research with an open mind about a new product, it’s amazing what you can learn about how wonderful ecoFINISH really is.

Pool Magazine: Well, I appreciate that, Jake. Honestly, thanks so much for taking the time out today to join us on the show and share your experience and expertise with using ecoFINISH. I know there’s a lot of pool contractors out there who’ve been interested in learning more about the product. And hearing your firsthand experience is sure to be pretty helpful in their decision-making process.

Jacob Tetrick: Yeah, thank you for your time as well. I really appreciate it.

Pool Magazine: That’s all the time we have left today. Make sure to like, subscribe, follow, and we’ll catch you next time on another episode of the Pool Magazine podcast.

Part 2 – Joe Solana

Pool Magazine: Thanks for joining us on another episode of Pool Magazine Podcast. Today I have Joe Solana, president of ecoFINISH, a premier supplier of cutting-edge flame-sprayed polymer coatings for pool applications. It’s a pleasure to have you with us today on the show, Joe.

Joe Solana: Hi, thank you for having me.

Pool Magazine: You know, before we get deep into the weeds with our conversation, I thought it would be a good starting point if maybe you could provide our listeners with a brief introduction about who ecoFINISH is and what your firm specializes in.

Joe Solana: Yeah, ok, so ecoFINISH specializes in external flame-sprayed powder coating. We started off in the swimming pool industry through a sister company of ours, Carlton Pools, in Warminster, Pennsylvania. And when we developed the system, we had originally developed it for concrete swimming pools because that’s what we primarily specialized in.

And it was during the 2008-2009 recession. So for us, we realized that we had lost a lot of the new pool installations and we were focusing much heavier on renovations. So when we had developed the system, we had developed it for application on renovation of concrete swimming pools. But it didn’t take long before we realized that we could also develop installation techniques for fiberglass steel aluminum. So we have installation processes for multiple scenarios and different types of swimming pools.

How ecoFINISH Works

Pool Magazine: Well, one question that I’ve seen pop up again and again out there in Facebookland, is how does ecoFINISH actually work? I mean, can you shed some light on that for us, Joe?

Joe Solana: Yeah, so polyethylene powders, they’re chemical resistant with UV stable pigments. So when you apply them into a swimming pool, you won’t get your typical finish, I’m not going to speak in absolutes, if you abuse the finish, you can abuse the finish just like anything else. But it is much less likely to fade from water chemistry. So somebody throws muriatic acid in the pool and they dump it down one side of the wall. You’re not going to get a bleach mark from that. Or if somebody’s broadcasting chlorine and they dump an extra load onto the finish, it’s not going to bleach like you could get with a masonry finish. So you have time to find a pool brush and sweep it away or try and dissolve it before it actually starts to affect the finish. Because it’s a polyethylene finish, it’s also chemical resistant, or I should say it doesn’t impact the chemistry. So the curing process for our finish lasts a couple of minutes.

It’s essentially from the time that you stop applying the heat to the time it cools is our curing process. So as soon as the pool is finished or you’re finished installing the coating, you can fill with a garden hose. You don’t need trucked water. So if it takes a day or three days or five days to fill, it’s not the end of the world. And as soon as it is full, you can put your cleaner in the pool, you can turn your pool heater on, and you can start using the pool immediately. There’s no two week curing process like other finishes. So it makes it easy for the homeowner to start using the pool immediately and for the pool builder for that matter, for the ease of starting the pool up.

Flame-Spraying Process

Pool Magazine: Well, my friend Jake is a builder and he’s also an applicator that specializes in ecoFINISH installations. I spoke with him the other day and he told me that there’s a flamethrower involved somewhere in that process. Can you speak a little bit more about that?

Joe Solana: Yeah, so with our finish, external flamethrower powder coating, what that means is we’re taking the same science behind traditional powder coating, taking items and electrostatically spraying them with powders and popping them in an oven. We’re taking that same technology, but we’re moving it to surfaces that are too large to stick in an oven, right?

So we like to say that our finishes are good for any single side on a large surface. So you could do a wall pretty easily, but you couldn’t do a fence, right? If you were trying to do a fence, it would be much too difficult to try and get around all the nooks and crannies of a fence. But a swimming pool wall, it’s much easier. And the way that that’s applied is we’re taking those same powders. Chemically, they’re different because they have different properties than traditional powder coating. But we’re taking polyethylene powders. We’re running them through a hose as a dry powder. And when it makes it to the tip of our installation equipment, it passes through a flame and heat, which melts it, takes it to a liquid, right? And as it hits the wall, it’s being applied as a liquid. And as you progress further down the pool and you remove that heat, it starts to cool. And as that liquid cools, it starts to form a film over the substrate that it was applied to.

New Product – AquaSpada

Pool Magazine: You walk us through your product line a little bit. I see a few different things on your website, the aqua coatings, AquaSpada, and the liquid resin. Can you talk to that a little bit?

Joe Solana: Yeah, so ecoFINISH is a company started off with aquaBRIGHT. And that was to apply to concrete swimming pools for the most part. And as we realized that we could also apply to fiberglass pools or aluminum surfaces, we also realized that our marketing did not explain that very well. So to aquaBRIGHT, we added a line called polyFIBRO. And with polyFIBRO, the only difference besides the installation techniques is our marketing. Really, we just took some additional colors, created a second line, and we marketed it to fiberglass pools, aluminum pools, and fiberglass pool steps on vinyl liner pools during renovations, essentially to surfaces that are other than concrete.

We also have a lot of customers out there who have combinations of things. They have fiberglass walls and concrete floors where we had an old fiberglass pool that had a crack down the middle of it. And they removed the floor and put in a concrete floor. And then they coated the walls and the new concrete floor with our finish. We have customers who took pools that had cinder block walls and a concrete floor and they dropped a set of fiberglass steps and they coated everything in the same color. So polyFIBRO, we use that to catch all of that other work for marketing purposes.

We have a new product, which is AquaSpada. An AquaSpada is a device that converts H2O into H3O. And as it does that, it bonds essentially the molecules inside the water together so that they’re more easily filtered out. And for us, we felt that it was important for our customers to find ways to reduce scaling in the pools without constantly adding more chemicals, right? Because pretty much everything in our society is developed around disposable goods where you would just go out and buy more, right? So we had an opportunity to work with PoolTiger to carry their product. And we were very pleased that we were able to offer a product that our customers can install that does not have any electric ran to it and doesn’t require routine maintenance, doesn’t require additional chemicals, but yet can still reduce the calcium inside of a swimming pool with a lifetime warranty.

There’s not many products that will do that. And we tried the unit for a considerable amount of time, an entire year, before we actually felt like it was something that we wanted to offer because it does kind of seem too good to be true. When we started installing polyethylene coatings to concrete, it didn’t take very long for new applicators to want to offer our coatings in areas or surfaces that it was never really intended for. And so quickly guys said, well, you know, can we take your coatings and apply them to garage floors? Right?

That was one that a lot of guys normally say. And we have no marketing offering our material on garage floors. And in fact, we don’t recommend it. We feel that it’s much too dangerous shooting an open flame against drywall in somebody’s house. It just is destined to be an issue. So we do not recommend it in any way, shape or form.

And we try to steer guys away from it. At the same time, we had other applicators coming to us and saying that they wanted to use the finish on swing pool decks, right? Because they’re concrete and our methods of adhesion work very well under water. And they also work very well above water.

So we had other guys who wanted to do that. And for me, I just don’t like the way the finish looks above water. It has a kind of a glossy finish to it. And I prefer that deck coatings have more of a matte finish to them.

So they look a little bit more natural. So I knew that there were needs out there for swimming pool contractors who wanted to do other work. They wanted to do basements or they wanted to do garage floors or they wanted to do swimming pool decks with some type of coating that adheres well that is relatively maintenance free. And I also felt like flame spray coatings were not the answer. When you’re installing powder coatings to concrete, they won’t adhere on their own. They cool much too fast to properly bond to the surface. They don’t typically run into the pores of concrete like a liquid resin would.

So in order to install powder coating on poor surfaces like concrete, you have to use some type of primer. And the primer that we use is an epoxy primer that we’ve used since the first day that we were doing installations back in 2008, I think. And so to this day, we still use the same base resins that we used at that time because they work so well, especially in damp surfaces. You can install our epoxies on green concrete. You can install them on concrete that still has some humidity in them. They’re not affected by humidity. If anything, they probably would prefer to go off a little bit quicker in high humid situations, depending on which epoxy you’re working with. We have several types. But the company that we are working with and that we found these epoxies through is in the UK.

It’s on the Whirl Peninsula, just south of Liverpool. And as we were working with them, we formed a really good relationship with them. And knowing that we had customers who were looking for answers to problems that we did not feel our products were really handling and knowing that the people that we were working with over in the UK were looking to retire, the ownership was looking to retire. We made an offer to purchase the company right before COVID happened back, I guess it was at this point, 2020 maybe. And we ended up purchasing their company. So we still have employees working in the UK right now as a separate company.

That’s Optus Resin Technology. And they’re currently supplying products to their customer base in the UK. And then what we’re doing is we’re working with them developing new products here in the US. We have several liquid resins that we work with for various purposes. So for instance, we develop a product that we call Floaterra, which is a thicker floater self-leveling finish. So it goes on thick, you apply it to surfaces that maybe aren’t perfectly smooth.

It goes on heavier than a simple rollout resin. So it could take out some inconsistencies. It’s really meant for us. We’re promoting it towards foyers to swim clubs, that kind of stuff.

You could use it in locker rooms as well. But we also have another version of that that we call Floaterra Flex, which is also a floater sinker stuff leveler, but it has some cushion to it. So it can be applied with a top coat that we put a polycarbonate chip in to give it a little bit of texture.

So it’s soft on the foot, but it has a little bit of texture to it. And then in that same top coat, we can also put an antimicrobial additive in it. So the intention is for locker rooms, even shower facilities in swim clubs. So our dealers then can go to a swim club and they can offer our finish in the swimming pool and then they can offer a finish for inside their locker rooms or inside the foyer areas for the customers.

Commercial Coatings and Beach Entry Coatings

Pool Magazine: So you’ve got these commercial coatings, I see. And you’ve also got beach entry coatings as well, right? Yeah.

Joe Solana: Well, when you go to do swimming pools commercially, one of the first things that comes up when you’re talking about water parks is slip and falls, right? One of the major pool parks that we were working with said that they get a lawsuit every single day they have a new lawsuit presented to them. So slip and fall is very important when it comes to commercial facilities. So that would lead directly into zero entries, right? When you’re talking about walking into a pool from deck level into the water and, you know, people are sometimes drinking, right?

I mean, there’s a lot that could potentially happen. Older people… There’s no handrails and zero entries often. So any type of finish going into those typically they like to see a pretty abrasive coating. So with that, we have a beach entry coating, which is our finish with a kind of a harsh abrasive into it to give texture. I wouldn’t use it in a residential situation, but in a commercial situation, absolutely, especially in, say, a wave pool, right? Where there’s a lot going on and people are probably falling all the time. Right.

Training and Support

Pool Magazine: Well, what kind of training and support does ecoFINISH provide all contractors that are interested in installing their products?

Joe Solana: So, yeah, that’s a good question. Early on, we had made the decision. We were the ones introducing this technology. I don’t think there’s anybody in the world who powder coats as a company who does external flames spray powder coating to the extent that we do, especially on concrete.

I don’t think there’s very few people even attempting to do what we do because it’s so difficult. So we knew when we were introducing a new technology into the swimming pool industry that if anything went wrong and the applicators were not installed correctly and they were having issues that the product would be to blame.

It’s not like, you know, having some type of cementitious plaster finish and just coming out with a new brand, right? You come out with a new brand and guys don’t install it correctly… usually the applicator is the one who can easily be explained to be doing it incorrectly and the reason for the problem. But when you have a whole new technology and you’re introducing it into an industry, that’s never heard of before and you’re asking people to believe that it works. If you run into any streak of issues, everyone’s going to blame the new technology.

They wouldn’t blame a poor application. So we knew that we had enough to battle. And I’ve been in the swimming pool industry my entire life, right? I was born into the family business, right? And so I know the kind of guys that we deal with on a day to day basis. And often if presented with needing to pay for training, they’ll opt to skip it.

So we made the decision early on that we would never charge anybody for training. And we have applications all over the world. We have applications in the United States, Canada, Costa Rica, Panama, Fiji, all the way throughout Europe into Australia. And out of those, other than the initial purchase of the equipment, I can only think of one or two instances where we actually charge somebody for training. And that was really just a couple outlier reasons. Any one of our customers, one of the points that we hit on is that we will get people to them doing a process that’s for any reason, right?

If they’re just uncomfortable and they need help, all they have to do is ask. And that’s true in the swimming pool industry. A lot of guys who do concrete pools only do concrete pools, right? Guys who do fiberglass bowls, typically they only do fiberglass bowls. There’s a handful of companies out there where they’ll jump around and they’ll do fiberglass. They’ll do concrete. They’ll do vinyl liners. But there’s not a ton of those guys, right? The vast majority, they specialize in something, then they stick with it.

So if you’re a concrete guy and that’s what you’re used to and that’s what we trained you on, and you go to do your first fiberglass pool, we not only do we want you to ask for help, we want to be there. We want to show you how to do it because there are subtle differences between the two. We have many guys who will go out and will train the team and they lose their head installer. And when they lose their head installer, they now move that second guy into the first position and he might not be ready for it.

He may be, but usually not. So they need new training. And so these are all instances where we want somebody to call us and tell us where and when and we’ll try and get somebody there. You can’t call today and say you need somebody next week. And a lot of guys do that, right? A lot of guys will say, oh, I have a very important job next week.

Well, we’re kind of booked out at that point. But in the US, we have two full-time trainers, plus our sales staff also trains. And then we have people inside our office who work in other facets of the company, but they also know how to train people if needed. And then in Europe, we have two full-time trainers and we’re trying to bring a third one on. And these are the same people that will move all over the world. We’re going to be in Australia, I think, next week for training. So we have no problem going wherever we need to go. Someone in the United States is very easy to hit.

Pool Magazine: Yeah, I know my friend Jake is in South Dakota. I mean, it’s not typically known as a hot market for pool installation. And he had Cory Anderson out there coaching him through the installation process. I could definitely tell that you guys support the product.

Joe Solana: Yeah. And if he needed us to come out again, we would send somebody back out again, like I said, that was very important to me that I knew that if anybody felt like they needed training, but they were forced to pay us to come back out, that they wouldn’t do it. So all they have to do is ask.

Becoming an Installer or Dealer

Pool Magazine: Well, that’s awesome. If people are interested in becoming an installer or a dealer, how do they go about getting on with ecoFINISH?

Joe Solana: Well, the easiest place to learn more is www.ecofinishcoatings.com. That’s the easiest place. And they can find all the information that they want right there.

Pool Magazine: Thanks so much for taking the time out to connect with us today and for educating us a little bit more about the product. I really enjoyed our conversation today, Joe.

Joe Solana: No, thank you for having me. I greatly appreciate it.

Pool Magazine: Well, that’s all the time we have left for today. Make sure to like, subscribe, follow, and we’ll catch you next time on another episode of Pool Magazine Podcast.